+31 85 0410121

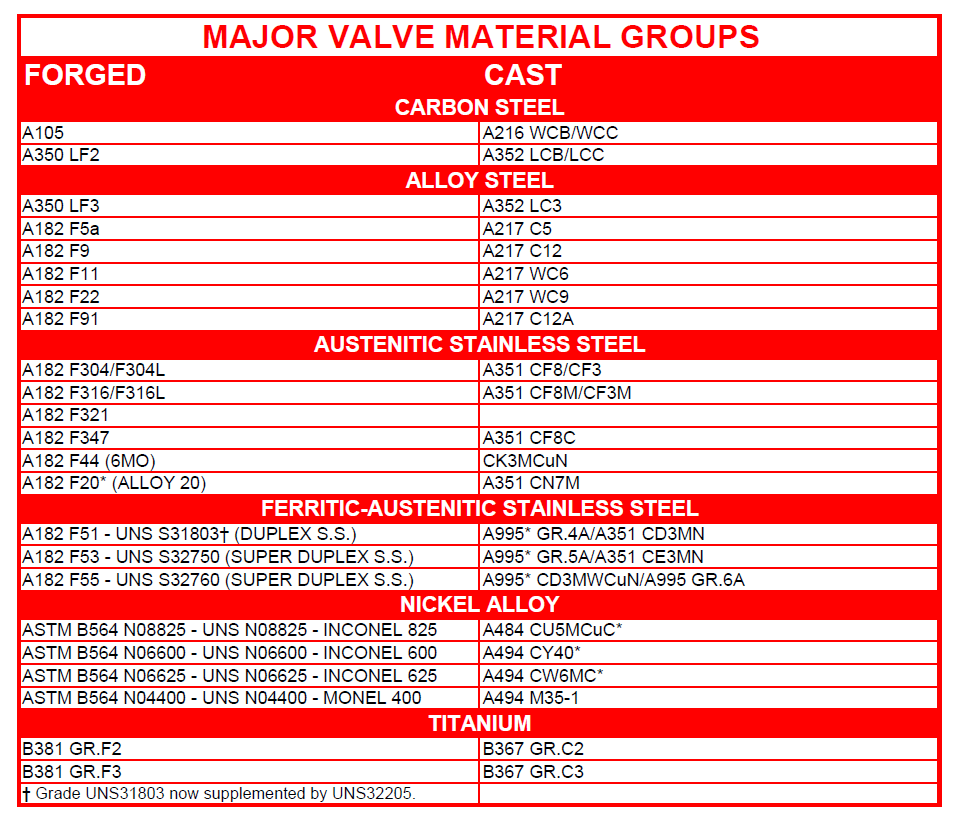

Valve cast forged material

Below you find several reference sheets for all your comparing needs. Missing something? Please let us know!

- Cross reference material list ASTM, DIN, UNS, cast, forged, fittings, flanges & pipe

- Material groups

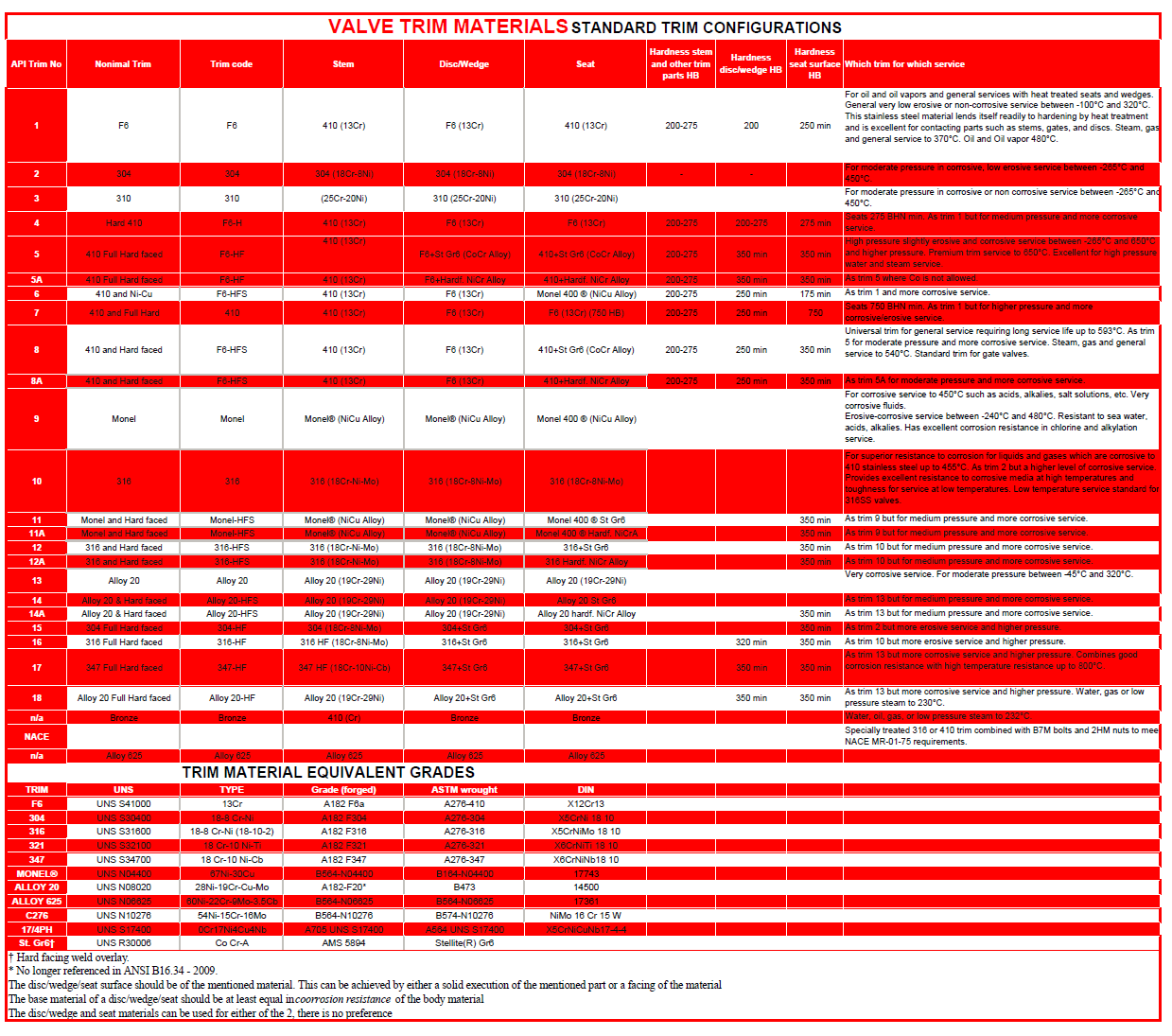

- Trim

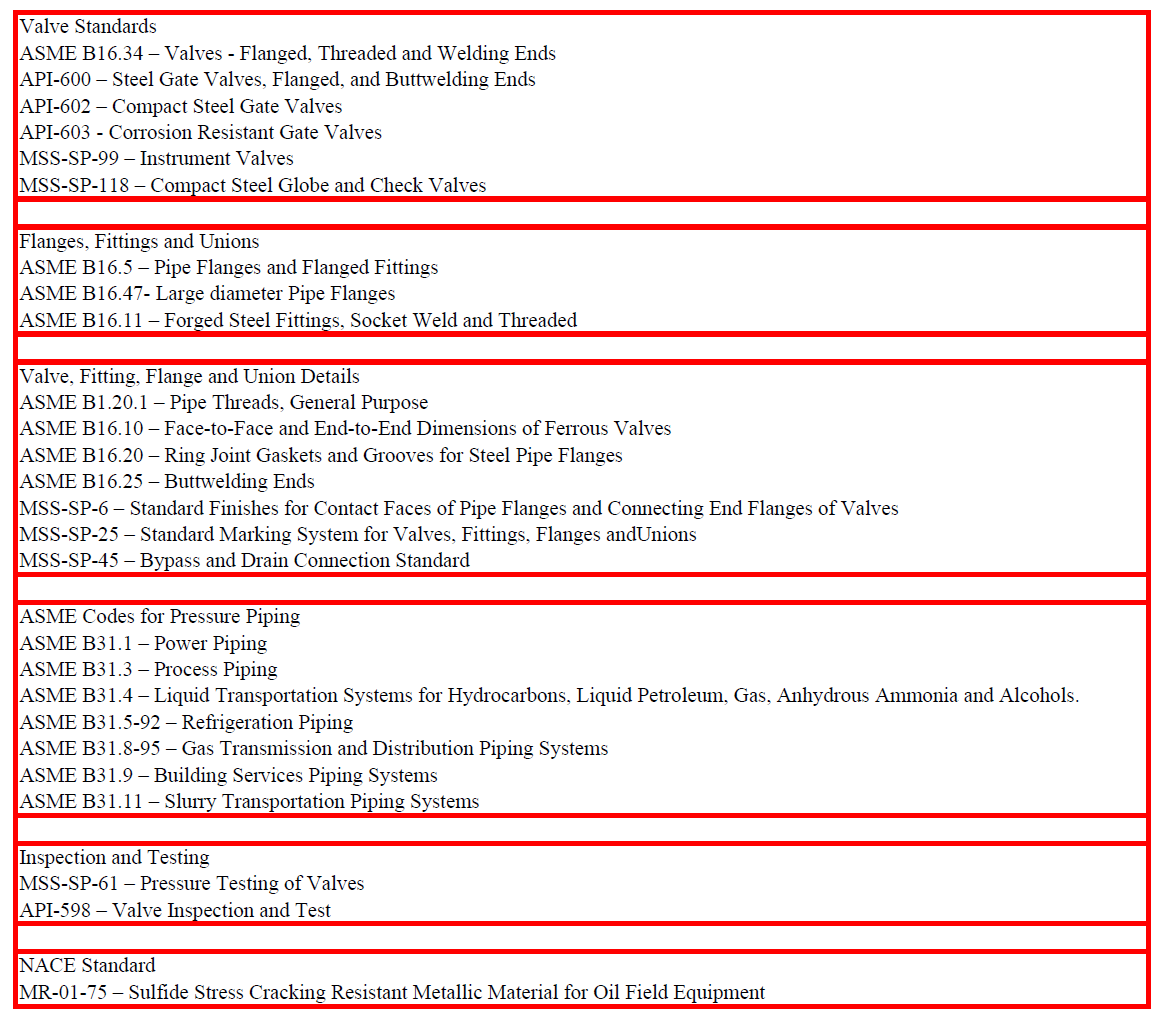

- Valve related standards

- Abbreviations and terms

- Bolting material specifications

Click on the relevant picture to get the PDF with all the information.

Send your enquiry to sales@invalved.eu

Cross reference material list ASTM, DIN, UNS, cast, forged, fittings, flanges & pipe

Material Group

Common Name

Material Type

Forging Spec

UNS

Casting Spec. Equivalent

Butt Weld Fittings

Pipe

DIN

DIN W.

No

EN 10216

Application casting

Carbon Steel

CS

C-Mn-Fe

A105/A105N/A106

K03504

A216-WCB, WCC

A234-WPB

A105-Gr.B/API5LB

C22.8 DIN 17243

1.046

Non-corrosive applications including water, oil and gases at temperatures between -20°F (-30°C) and +800°F (+425°C)

Low Temperature Carbon Steel

LTCS

C-Mn-Fe

A350-LF2

K03011

A352-LC1

A420-WPL6

A333-Gr.6

TSTE 355 DIN 18103

1.0566

Low temperature applications to -75°F (-59°C). Not for use above +650°F (+340°C).

2-1/2 Ni

A352-LC2

Low temperature applications to -100°F (-73°C). Not for use above +650°F (+340°C).

C-Mn-Fe

A352-LCB

Low temperature applications to -50°F (-46°C). Not for use above +650°F (+340°C).

C-Mn-Fe

A352-LCC

Low Temperature Alloy Steel

Nickel Steel

3.1/2Ni

A350-LF3

K32025

A352-LC3

A420-WPL3

A333-Gr.3

10Ni14

1.5637

Low temperature applications to -150°F (-101°C). Not for use above +650°F (+340°C).

Low Alloy Steel

Moly Steel

C-1/2Mo

A182-F1

K12822

A217-WC1

A234-WP1

A335-Gr.P1/A691 CM-70

15Mo3

1.5415

Up to 875ºF (468ºC)

1/2Cr-1/2Mo Alloy Steel

A182-F2

A691 CM-75

Alloy Steel Chrome Moly

1.1/4Cr-1/2Mo

A182-F11 cl2

K11572

A217-WC6

A234-WP11 CL2

A335-Gr.P11

13CrMo44

1.7335

Non-corrosive applications including water, oil and gases at temperatures between -20°F (-30°C) and +1100°F (+593°C).

1Cr-1/2Mo Alloy Steel

A182-F12 CL2

A217-WC6

A234-WP12 CL2

A335-Gr.P12

2.1/4Cr-1Mo

A182-F22 cl3

K21590

A217-WC9

A234-WP22 CL3

A335-Gr.P22

10CrMo910

1.738

Up to 1100ºF (593ºC), HP steam

5Cr-1/2Mo Alloy Steel

A182-F5

A234-WP5

A335-Gr.P5

5Cr-1/2Mo

A182-F5a

K41545

A217-C5

12CrMo195

1.7362

Mild corrosive or erosive applications as well as non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+649°C).

9Cr-1Mo

A182-F9

A217 C9

Non-corrosive applications including water, oil and gases at temperatures between -20°F (-30°C) and +1100°F (+593°C).

K90941

A217-C12

A234-WP9

A335-Gr.9

X 12 CrMo 9 1

1.7386

Mild corrosive or erosive applications as well as non-corrosive applications at temperatures between -20°F (-30°C) and +1200°F (+649°C).

9Cr-1Mo-V

A182-F91

A217-C12A

A335-Gr.91

X 10 CrMoVNb 9 1

1.4903

High pressure steam

A217 CA15

Corrosive application at temperatures up to +1300°F (+704°C)

Stainless Steel

Austenitic

Austentic S.Steel 300 series S.Steel

304 : 18Cr-8Ni

A182-F304

S30400

A351-CF8

A403-WP304

A321-TP304

DIN X5CrNi 18 9

1.4301

Corrosive or extremely high temperatures non-corrosive services between -450°F (-268°C) and +1200°F (+649°C). Above +800°F (+425°C) specify carbon content of 0.04% or greater.

304L : 18Cr-8Ni

A182-F304L

S30403

A351-CF3, A351-CF3A

A403-WP304L

A312-TP304L

X 2 CrNi 19 11

1.4306

Corrosive or non-corrosive services to +800F (+425°C).

304H :

A182-F304H

S30409

A351-CF10

A403-WP304H

A312-TP304H

Type 310 Stainless Steel 25Cr-20Ni

A182-F310H

A351-CK20

A403-WP310

A312-TP310

316 : 16Cr-12Ni-2Mo

A182-F316

S31600

A351-CF8M

A403-WP316

A312-TP316

X5CrNiMo 18 10

1.4401

Corrosive or either extremely low or high temperature non-corrosive services between -450°F (-268°C) and +1200°F (+649°C). Above +800°F (+425°C) specify carbon content of 0.04% or greater.

316L : 16Cr-12Ni-2Mo

A182-F316L

S31603

A351-CF3M

A403-WP316L

A312-TP316L

X 5 CrNiMo 17 12 2

1.4404

Corrosive or non-corrosive services to +800F (+425°C).

316H :

A182-F316H

S31609

A351-CF10M

A403-WP316H

A312-TP316H

316Ti :

A182-F316 Ti

S31635

X 6 CrNiMoTi 17 12 2

1.4571

Special grade

Type 317 Stainless Steel 18Cr-13Ni-3Mo

A182-F317

A351-Gr.CG8M**

A403-WP317

A312-TP317

Type 317 Stainless Steel 18Cr-13Ni-3Mo

A182-F317H

A351-Gr.CF8A

317L

A182-F317L

S31703

A351-CG3M*

X2CrNiMo18-16-4

1.4438

321 : 18Cr-10Ni-Ti

A182-F321

S32100

A403-WP321

A312-TP321

X 6 CrNiTi 18 10

1.4541

0.04%min. carbon (grade F321H) and heat treat at 2000ºF (1100ºC) for service temps. >1000ºF (538ºC)

321H

A182-F321H

S32109

A403-WP321H

A312-TP321H

347 : 18Cr-10Ni-Cb(Nb)

A182-F347

S34700

A351-CF8C

A403-WP347

A312-TP347

8556

1.455

Primarily for high temperature, corrosive applications between -450°F (-268°C) and +1200°F (+649°C). Above +1000°F (+540°C) specify carbon content of 0.04% or greater.

347H

A182-F347H

S34709

A403-WP347H

A312-TP347H

Type 348 Stainless Steel 18Cr-10Ni-Cb

A182-F348

A403-WP348

A312-TP348

Type 348 Stainless Steel 18Cr-10Ni-Cb

A182-F348H

A403-WP348H

A312-TP348H

Alloy

Alloy 20

28Ni-19Cr-Cu-Mo

A182-F20*

N08020

A351-CN7M†

14.500

2.466

Good resistance to hot sulfuric acid to +800F (+425°C).

Duplex

Duplex 2205

22Cr-5Ni-3Mo-N

A182-F51

S31803

A351-CD3MN (A995-4A)*

S31803/S32205†

A789/A790-UNS31803

X2CrNiMoN22-5-3

1.4462

Very high strength, resistance to corrosion, pitting and stress corrosion in chloride media. Service to 600ºF (316ºC) - The original S31803 UNS designation has been supplemented by S32205 which has higher minimum N,CR, and Mo

S32205

J92205 (A995-4A)*

10088-1 (95)

Super Austenitic

Super Austenitic/ 6Mo

20Cr-18Ni-6Mo

A182-F44

S31254

A351-CK3MCuN

S31254

A312-UNS S31254

X1CrNiMoCuN20-18-7

1.4547

Very high strength, high resistance to corrosion. Service to 600ºF (316ºC)

10088-1 (95)

Super Duplex

Super Duplex 2507

25Cr-7Ni-4Mo-N

A182-F53

S32750

A351-CD4MCu*

S32750

A789/A790-UNS32750

X2CrNiMoN27-7-4

1.4501

Service to 600ºF (316ºC)

A995-5A*/CE3MN

10088-1 (95)

Super Duplex F55

25Cr-7Ni-3.5Mo-N-Cu-W

A182-F55

S32760

A995-CD3MWCuN (A995-6A)

S32760

A789/A790-UNS32760

Service to 600ºF (316ºC)

Nickel-Iron Alloy

Incoloy 800

33Ni-42Fe-21Cr

B564-N08800

N08800

X10NiCrAlTi32-20

1.4876

Service to 1000ºF (538ºC)

Incoloy 825

42Ni-21.5Cr-3Mo-2.3Cu

B564-N08825*

N08825

A494-CU5MCuC*

17744

2.4858

Service to 600ºF (316ºC) for N02200, 1200ºF (648ºC) for N02201

Nickel

99/95Ni

B160-N02200

(bar)

N02200

A494-CZ-100*

NW2200

1.7740

Nickel-Copper

Monel 400

67Ni-30Cu

B564-N04400

N04400

A494-M35-1

17730

2.4360

Good resistance to corrosion by all common organic acids and salt water. Also highly resistant to most alkaline solutions to +750°F (+400°C).

Monel 500

B564-N05500*

N05500

2.4375

Nickel-Alloy

904L

904L*

N08904

Z2 NCDU 25-20

1.4539

Nickel Superalloys

Inconel 600

72Ni-15Cr-8Fe

B564-N06600

N06600

A494-CY40*

17742

2.4816

Very good for high temperature service. Good resistance to spanly corrosive media and atmosphere to +800°F (+425°C).

Inconel 625

60Ni-22Cr-9Mo-3.5Cb

B564-N06625

N06625

A494-CW-6MC*

2.4856

Hastelloy B

A743 N-12M

Is well suited for handling hydrofluoric acid at all concentrations and temperatures. Good resistance to sulphuric and phosphoric acids to +1200°F (+649°C).

Hastelloy C-276

A743 CW-12M

Good resistance to span oxidation conditions. Good properties at high temperatures. Good resistance to sulphuric and phosphoric acids to +1200°F (+649°C).

Hastelloy C-276

54Ni-15Cr-16Mo

B564-N10276

N10276

A494-CW-2M*

NiMo 16 Cr 15 W

2,4819

Titanium

98Ti

B381-Gr2

R50400

B367-C2*

Ti 2

3,7035

Good resistance to corrosion together with low specific weight.

† Cast CN7M only rated to 150ºC, however ‘New Alloy 20’ grade CN3MCu is available which is to be rated to at least 316ºC.

* No longer referenced in ANSI B16.34 - 2009, A995 supersedes A990 (meets & surpasses).

Valve Standards

ASME B16.34 – Valves - Flanged, Threaded and Welding Ends

API-600 – Steel Gate Valves, Flanged, and Buttwelding Ends

API-602 – Compact Steel Gate Valves

API-603 - Corrosion Resistant Gate Valves

MSS-SP-99 – Instrument Valves

MSS-SP-118 – Compact Steel Globe and Check Valves

Flanges, Fittings and Unions

ASME B16.5 – Pipe Flanges and Flanged Fittings

ASME B16.47- Large diameter Pipe Flanges

ASME B16.11 – Forged Steel Fittings, Socket Weld and Threaded

Valve, Fitting, Flange and Union Details

ASME B1.20.1 – Pipe Threads, General Purpose

ASME B16.10 – Face-to-Face and End-to-End Dimensions of Ferrous Valves

ASME B16.20 – Ring Joint Gaskets and Grooves for Steel Pipe Flanges

ASME B16.25 – Buttwelding Ends

MSS-SP-6 – Standard Finishes for Contact Faces of Pipe Flanges and Connecting End Flanges of Valves

MSS-SP-25 – Standard Marking System for Valves, Fittings, Flanges andUnions

MSS-SP-45 – Bypass and Drain Connection Standard

ASME Codes for Pressure Piping

ASME B31.1 – Power Piping

ASME B31.3 – Process Piping

ASME B31.4 – Liquid Transportation Systems for Hydrocarbons, Liquid Petroleum, Gas, Anhydrous Ammonia and Alcohols.

ASME B31.5-92 – Refrigeration Piping

ASME B31.8-95 – Gas Transmission and Distribution Piping Systems

ASME B31.9 – Building Services Piping Systems

ASME B31.11 – Slurry Transportation Piping Systems

Inspection and Testing

MSS-SP-61 – Pressure Testing of Valves

API-598 – Valve Inspection and Test

NACE StandardMR-01-75 – Sulfide Stress Cracking Resistant Metallic Material for Oil Field Equipment

CA6NM Abbreviations & terms used in the valve industry

AARH

Arithmetic Average Roughness Height

AISI

American Iron and Steel Institute

API

American Petroleum Institute

ANSI

American National Standards Institute

ASME

American Society of Mechanical Engineers

ASTM

American Society for Testing and Materials

AWS

American Welding Society

BB

Bolted Bonnet

BHN

Brinell Hardness Number

Btu

British Thermal Unit

BWE

Butt Weld Ends

C or Cel

Celsius degrees

Cl

Cast Iron

Cl

Chlorine Institute

CR 13

13% Chromium Stainless Steel

CRES

Corrosion Resistant Steel

C v

The number of U.S. gallons per minute of water at 70°F which will flow through a valve at a pressure drop of one psi.

CWP

Cold Working Pressure

DN

Diameter Nominal (Metric)

ELL

Elbow

FAS

Free Alongside Steamer

F or Fahr

Fahrenheit degrees

F & D

Faced and Drilled

FF

Flat Face

FHF

Full Hard Faced

FLG

Flanged

FOB

Free on Board

FTTG

Fitting

G

Gas

gpm

Gallon per Minute

HF

Hard Faced

HW

Handwheel

ID

Inside Diameter

INT

Integral

ISRS

Inside Screw Rising Stem

ISNRS

Inside Screw Non. Rising Stem

Kg

Kilograms km

Kilometers

LH

Left Hand

MAV

Motor Actuated Valve

mm

Millimeter

MOV

See MAV

MSS

Manufacturers Standardization Society of the Valve & Fitting Industry

NACE

National Association of Corrosion Engineers (Formerly NACE International)

NPS

Nominal Pipe Size

NPT

National Standard Pipe Thread Taper

NRS

Non Rising Stem

OD

Outside Diameter

One Piece Stem

An inseparable Stem and Disc made from one piece of metal.

OS&Y

Outside Screw and Yoke

OWG

Oil, Water & Gas (See CWP)

PN

Pressure Nominal (Metric)

Psi

Pounds per square inch

Psia

Pounds per square inch absolute

Psig

Pounds per square inch gage

PT

Pressure Temperature

Rc

Rockwell “C”

RF

Raised Face

RH

Right Hand

RMS

Root Mean Square Roughness Height

RS

Rising Stem

RTJ

Ring Type Joint

S

Steam

SAE

Society of Automotive Engineers

SC

Swing Check Valve

Sch. or Sched.

Schedule (Pipe Wall Thickness)

SCFM

Standard Cubic Feet per Minute

Screw Bonnet

Body and Bonnet Threaded

Together SE

Screwed Ends

Seal Weld

Threaded Joint Back Welded for Seal

SS

Stainless Steel

Stem Nut

Operating Nut

Stuffing Box

Packing Chamber

STD

Standard Wall Thickness

Stop Check

A Check valve in which the closure member can be mechanically closed.

SWE

Socket Weld End

SWP

Steam Working Pressure

T

Tee Valve

Thd.

Threaded

TIR

Total Indicator Reading

UB

Union Bonnet

W

Water

Wedge

Gate

WOG

Water, Oil and Gas (See CWP)

WSP

Working Steam Pressure

WWP

Working Water Pressure

XS

Extra Strong Wall Thickness

XXS

Double Extra Strong Wall Thickness

Y

Wye Valve

Yoke Bushing

Operating Stem Nut

Yoke Nut

Stem Nut

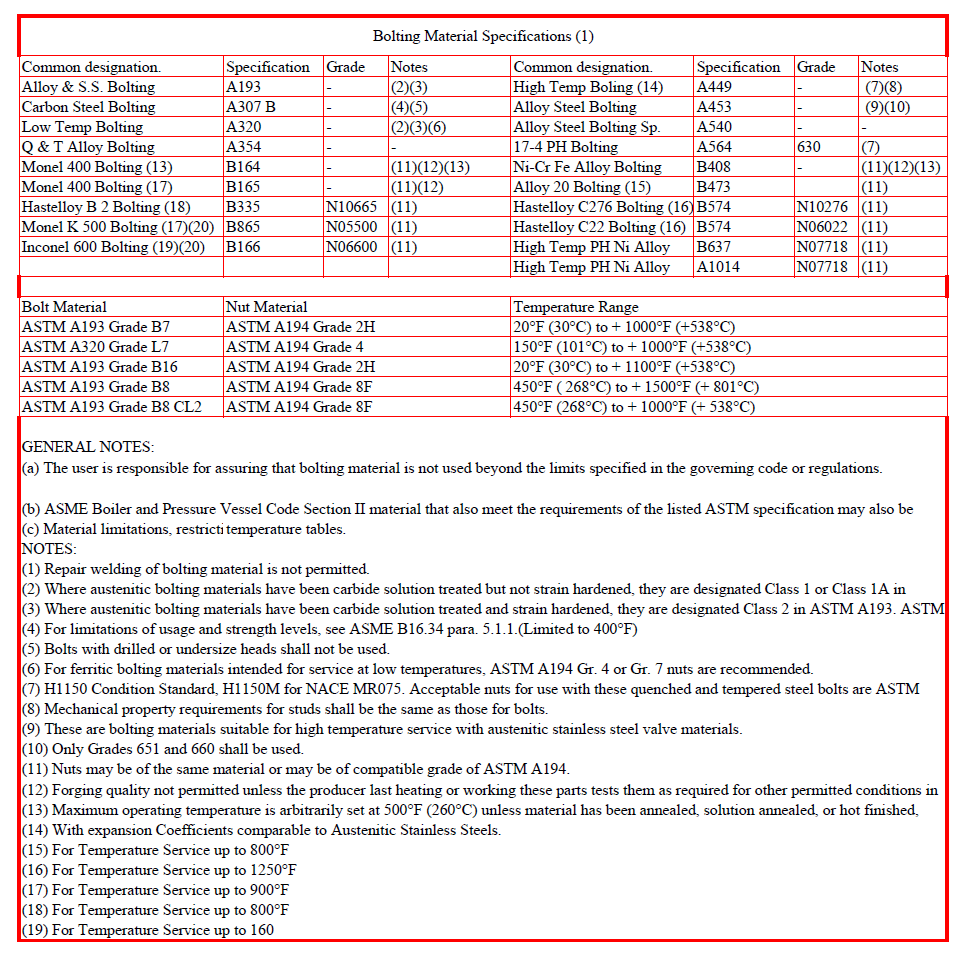

Bolting Material Specifications (1)

Common designation.

Specification

Grade

Notes

Common designation.

Specification

Grade

Notes

Alloy & S.S. Bolting

A193

-

(2)(3)

High Temp Boling (14)

A449

-

(7)(8)

Carbon Steel Bolting

A307 B

-

(4)(5)

Alloy Steel Bolting

A453

-

(9)(10)

Low Temp Bolting

A320

-

(2)(3)(6)

Alloy Steel Bolting Sp.

A540

-

-

Q & T Alloy Bolting

A354

-

-

17-4 PH Bolting

A564

630

(7)

Monel 400 Bolting (13)

B164

-

(11)(12)(13)

Ni-Cr Fe Alloy Bolting

B408

-

(11)(12)(13)

Monel 400 Bolting (17)

B165

-

(11)(12)

Alloy 20 Bolting (15)

B473

(11)

Hastelloy B 2 Bolting (18)

B335

N10665

(11)

Hastelloy C276 Bolting (16)

B574

N10276

(11)

Monel K 500 Bolting (17)(20)

B865

N05500

(11)

Hastelloy C22 Bolting (16)

B574

N06022

(11)

Inconel 600 Bolting (19)(20)

B166

N06600

(11)

High Temp PH Ni Alloy

B637

N07718

(11)

High Temp PH Ni Alloy

A1014

N07718

(11)

Bolt Material

Nut Material

Temperature Range

ASTM A193 Grade B7

ASTM A194 Grade 2H

20°F (30°C) to + 1000°F (+538°C)

ASTM A320 Grade L7

ASTM A194 Grade 4

150°F (101°C) to + 1000°F (+538°C)

ASTM A193 Grade B16

ASTM A194 Grade 2H

20°F (30°C) to + 1100°F (+538°C)

ASTM A193 Grade B8

ASTM A194 Grade 8F

450°F ( 268°C) to + 1500°F (+ 801°C)

ASTM A193 Grade B8 CL2

ASTM A194 Grade 8F

450°F (268°C) to + 1000°F (+ 538°C)

GENERAL NOTES:

(a) The user is responsible for assuring that bolting material is not used beyond the limits specified in the governing code or regulations.

(b) ASME Boiler and Pressure Vessel Code Section II material that also meet the requirements of the listed ASTM specification may also be used.

(c) Material limitations, restrictions, and special requirements are shown on pressure

temperature tables.

NOTES:

(1) Repair welding of bolting material is not permitted.

(2) Where austenitic bolting materials have been carbide solution treated but not strain hardened, they are designated Class 1 or Class 1A in ASTM A193. ASTM A194 nuts of corresponding material are recommended.

(3) Where austenitic bolting materials have been carbide solution treated and strain hardened, they are designated Class 2 in ASTM A193. ASTM A194 nuts of corresponding material are recommended.

(4) For limitations of usage and strength levels, see ASME B16.34 para. 5.1.1.(Limited to 400°F)

(5) Bolts with drilled or undersize heads shall not be used.

(6) For ferritic bolting materials intended for service at low temperatures, ASTM A194 Gr. 4 or Gr. 7 nuts are recommended.

(7) H1150 Condition Standard, H1150M for NACE MR075. Acceptable nuts for use with these quenched and tempered steel bolts are ASTM A194 Grade 2 and 2H. A194 Grade 2HM for NACE MR075.

(8) Mechanical property requirements for studs shall be the same as those for bolts.

(9) These are bolting materials suitable for high temperature service with austenitic stainless steel valve materials.

(10) Only Grades 651 and 660 shall be used.

(11) Nuts may be of the same material or may be of compatible grade of ASTM A194.

(12) Forging quality not permitted unless the producer last heating or working these parts tests them as required for other permitted conditions in the same specification and certifies their final tensile, yield, and elongation properties to equal or exceed the other permitted conditions. requirements for one of the

(13) Maximum operating temperature is arbitrarily set at 500°F (260°C) unless material has been annealed, solution annealed, or hot finished, because hard temper adversely affects design stress in the creep rupture temperature range.

(14) With expansion Coefficients comparable to Austenitic Stainless Steels.

(15) For Temperature Service up to 800°F

(16) For Temperature Service up to 1250°F

(17) For Temperature Service up to 900°F

(18) For Temperature Service up to 800°F

(19) For Temperature Service up to 160

Corrosive application at temperatures between -20°F (-30°C) and +900°F (+482°C).